Press & Review

Looking for Hydomoving’s news? Click on the logos below, They talk about us!

Choose the multiple system solutions HydroMoving for your engine!

Oxyhydrogen produced on board & on demand

The HydroMoving system, through its patented electrolytic process, produces oxyhydrogen on-board and on demand (at the request of the engine load) using distilled water directly from a small tank with the benefit of safety and a very low power consumption.

Green Solution & Benefits

The advantages of this system are numerous. The most important is the substantial reduction of CO2 values (certified by international third parties) from -30% and up. The significant reduction of other pollutants such as CARBON MONOXIDE (CO) -90%, unburned hydrocarbons (HC) -88%, SULPHUR OXIDES and nitrogen oxides (SOx, NOx) by -50%, particulate matter (PM10 PM25) by about -80%. Consequently, the fuel consumption is reduced from 20% to 35% (depending on the type of engine and driving style).

The Compact system HydroMoving, saves you usage of fossil fuels such as gasoline, diesel, LPG and CNG. The system uses distilled deminerilized water with a minimum percentage of an electrolyte. Water produced by air conditioners and rainwater can also be used after a basic filtration of dust and dirt. The system guarantees the cleanliness of FAP filter without causing any clogging avoiding maintenance in the workshop. The calorific value of oxyhydrogen increases engine power unlike LPG installations. The system can also be applied to those engines not equipped for the second fuel injection without the side effects derived from LPG and CNG.

The HydroMoving system is the only one in the world capable to bring back the environment to its clean state making the air we breathe cleaner and drastically eliminating harmful emissions.

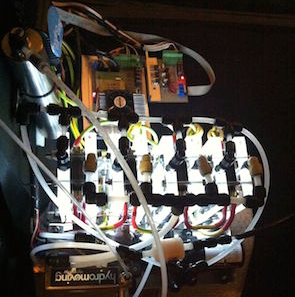

Hydromoving System it’s modular

The HydroMoving system is modular, it can be installed on any internal combustion engine. The number of cells installable start from 2 up to a multiple number of 6, dependent on the displacement and the type of the engine. The system it is equipped with sensors and electronic control which ensure the absolute safety of the entire installation. Our system absolutely DO NOT INCLUDE a storage tank of oxyhydrogen, making the system completely safe, unlike the common experimental projects using compressed hydrogen.

The Hydromoving CPU board and its displayed user interface makes this system simple to activate, use and monitoring.

Applications

The system can be installed on any car, truck or bus. It is also resizable for marine transportation construction equipment, heavy duty machinery and industrial use systems (ex: Power generator). Practically in any vehicle or system where an internal combustion engine it is used with any type of fuel. There isn’t no potentially dangerous, additional tank installed but only a compact system with small footprint (The compact system studied for cars occupies the space of a tower PC).

Installation cost

The HydroMoving system has a competitive cost in relation to the benefits that come from a sensible decrease in fuel consumption and a enormous decrease of pollutant emissions. It can be purchased and installed exclusively on our chain of authorized Hydromoving installers.

Hydromoving Systems

The Hydromoving modular system it’s able to fit any type of ICE (Iinternal Combustion Engine) vehicle

info

Base System

Car/Suv Minivan

3 H-Cells to 6 H-Cells

![]()

Multi cell modular system (2 to 12) to equip ICE from 1.2 liters to 6.0 liters displacement, gasoline or Diesel

Technical Specifications:

- Electronic control unit (CPU)

- From 2 to 12 electrolytic cells

- Power board with safety sensors and electronic

- Custom steel injectors from 2 to 12 cylinders

- Programmable on board display (Authorized personal only)

- Mini water tank and oxyhydrogen filter

info

Bus&Truck System

Bus&Truck

>60 HCell

<= 92 HCell

Modular system from 60 to 92 electrolytic cells able to equip ICE from 12 liters to 20 liters displacement

Specifiche tecniche:

- Multi cells system from 60 to 92 electrolytic cells

- Electronic control unit (CPU)

- Electronic power board with safety sensors

- Custom steel injectors from 6 – 8 - 12 cylinders

- Programmable on board display (Authorized personal only)

- 50-100 liters (13 – 26 USGal) water tank plus oxyhydrogen filter

- Custom electronic injection unit

- Remote data acquisition

info

Custom System

Industrial Equipment – Heavy duty machinery – Pleasure Boating - Naval

From 5 cbm/hrs to 100 cbm/hrs Oxyhydrogen

Systems are available on request or on Customer project. Composed of cabinet/rack of cells able to produce Oxyhydrogen from 5 to 100 cbm/hrs, to equip ICE from 0.1 to 15 mW

Technical Specifications:

- Custom solutions on request

info

Pro System

Car/Suv Minivan

3 H-Cells to 6 H-Cells

![]()

Multi cell modular system (2 to 12) to equip ICE from 1.2 liters to 6.0 liters displacement, gasoline or Diesel

Technical Specifications:

- Electronic control unit (CPU)

- From 2 to 12 electrolytic cells

- Power board with safety sensors and electronic

- Custom steel injectors from 2 to 12 cylinders

- Programmable on board display (Authorized personal only)

- Mini water tank and oxyhydrogen filter

info

Cogenerator Plants

Electro cogenerators & Engines

From 2 cbm/hrs to 10 cbm/hrs Oxyhydrogen

Modular system composed of Rack of electrolytic cells able to equip ICE installed on electro cogenerator from 2 liters to 100 liters of displacement

Technical Spefications:

- From 2 cbm/hrs to 10 cbm/hrs of oxyhydrogen gas

- Electronic control unit

- Project based custom systems

- Power board with safety sensors and electronic

- Custom steel injectors from 2 to 18 cylinders

- Dedicated electronic injection unit

- Reverse osmosis plant for deminerilized water

- 1000 liters water tank, deminerilized and rain water

We are experts

INNOVATIVE RESEARCH - WATER ELECTROLYSIS

The HydroMoving experience and innovation has been able to obtain hydrogen by electrolysis considerably reducing the use of energy, thanks to a study that lasted more than ten years and supported by two patents.

NEW ENGINE FUEL SOLUTION

Discover the reason of the high performance on the engine equipped with the hydromoving system

Software development - control unit system dedicated

The experience of the Hydromoving team on the electronic field and information technology has created and optimized the best software and hardware that control the entire system.

DEVELOPING BIFUEL ENGINE SYSTEM COGENERATION PLANTS

Cogeneration is a new technology that allows you to recover the heat produced by an internal combustion engine that generates electricity (power generator) and exploits it to heat offices, apartment buildings, factories, companies, workshops, etc ... We have also revolutionized this by applying our system to the cogenerator engine.

Latest works

NISSAN 370Z HYDROMOVING SYSTEM

Hydromoving compact System 6 cells on 3700cc engine.

BMW Hydromoving System

HydroC4, four cells Compact model mounted on a 3 liters turbo diesel engine

Smart

Hydro3C, compact model installed on a Smart 1liter gas engine

Nissan Z

HydroP6, Professional prototype model 6 cells installed on a 3.7 liters Nissan engine in USA.

NISSAN NV 200

Hydromoving compact system on 2000cc engine

Evoluzione GT

Mercedes ML

Hydromoving Compact System on Diesel 3.200cc Engine

Latest News

Here latest news from Hydromoving World

- Nuova Test Drive Alfa Romeo Brera Barcellona Pozzo di Gotto (Messina) Written on Monday, 15 May 2017 17:55

- Mazda Nuova Test Drive Officine Treviso Written on Monday, 15 May 2017 17:43

- Nuove implementazioni - Evoluzione GT Written on Thursday, 11 May 2017 10:18

Statistic

our data and statistics about the system

2000

Km with 1,5 liters of H2O

90

% less harmful emissions

30

% less CO2

2000000

Website Visits in Europe

SHORTLY ABOUT US

The company HydroMoving Srl was founded through the efforts of the engineer Lorenzo Errico who, with his passion for cars, electronics and innovation with regard to

We are the only ones in the world to have a patented technology, tested and certified for the production of oxyhydrogen gas (gas produced from distilled water) on board and on-demand, with electronic injection in the combustion chamber of any type of ICE (gasoline / Diesel etc ..) that reduces polluting emissions by 90%. The system guarantees a reduction of CO2 one the GHG gas > = 30%.

Company mission

Seek new solutions that allow the use of oxyhydrogen gas to obtain clean emissions at 100%. The use inside the system of distilled rain water, the condensation water from household air conditioners and the condensation water from the A/C system of the car itself.

- -30% CO2 30%

- -90% Exhaust emissions90%

- more or less +50% km then normal fuel 50%

MAPS

Hydromoving Srl Via SP Pedemontana, 12 66022 Fossacesia ( Chieti ) Uscita casello Autostradale A 14 Val di Sangro Abruzzo, Italy Email: info@hydromoving.com Telefono: +39 339 783 5888 https://www.hydromoving.com